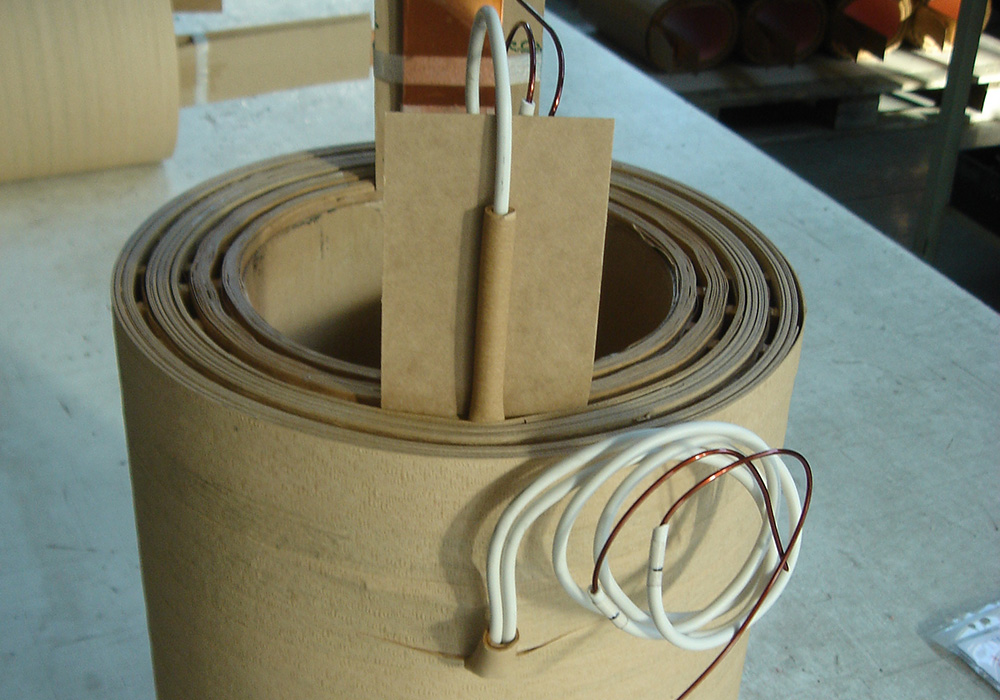

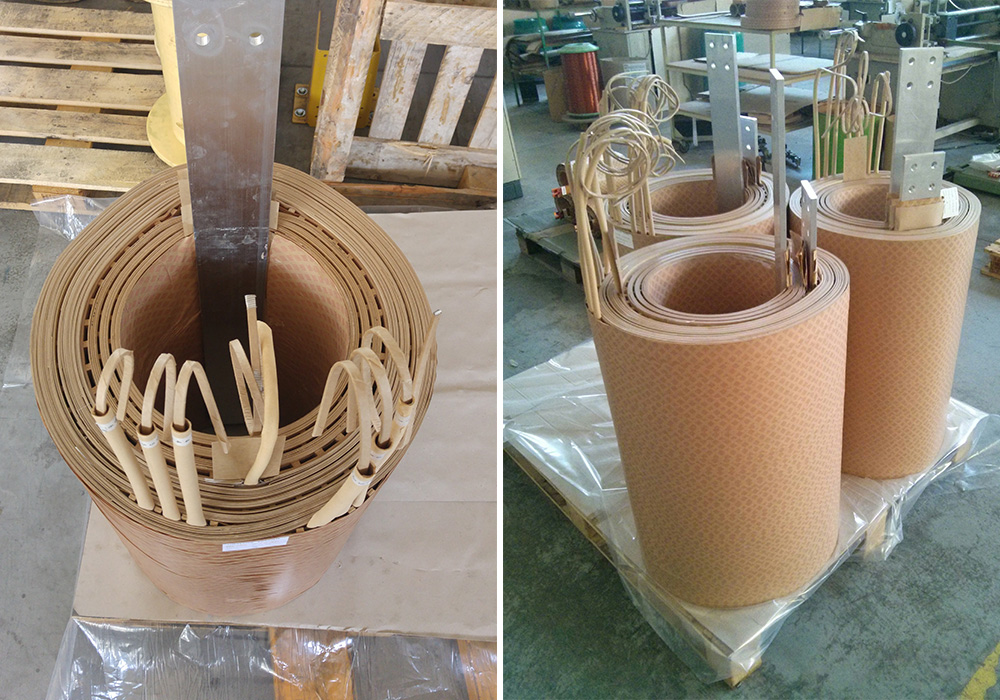

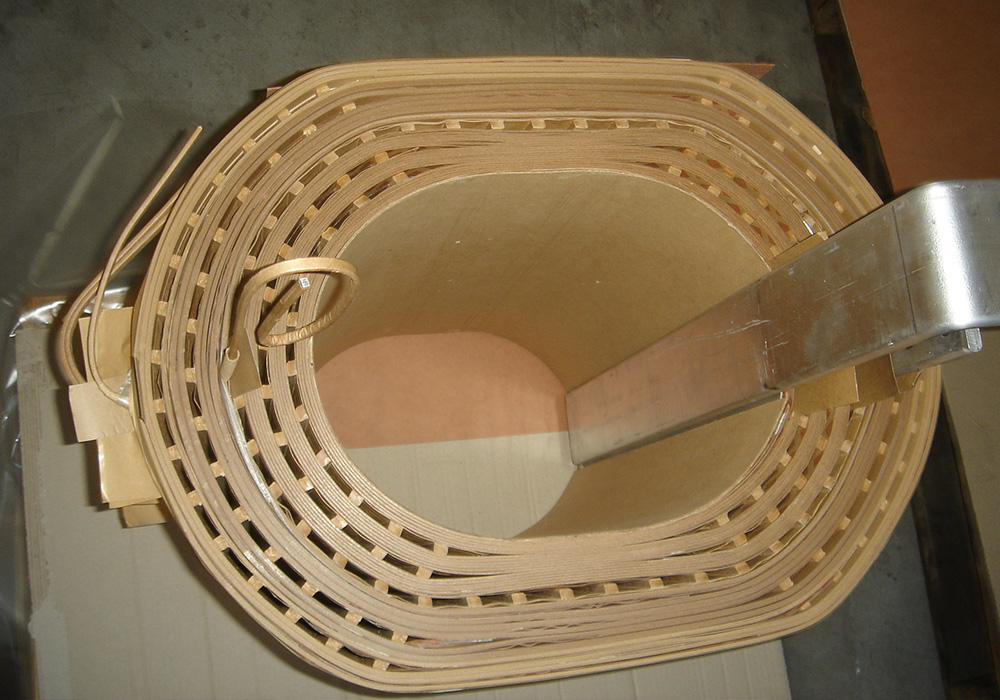

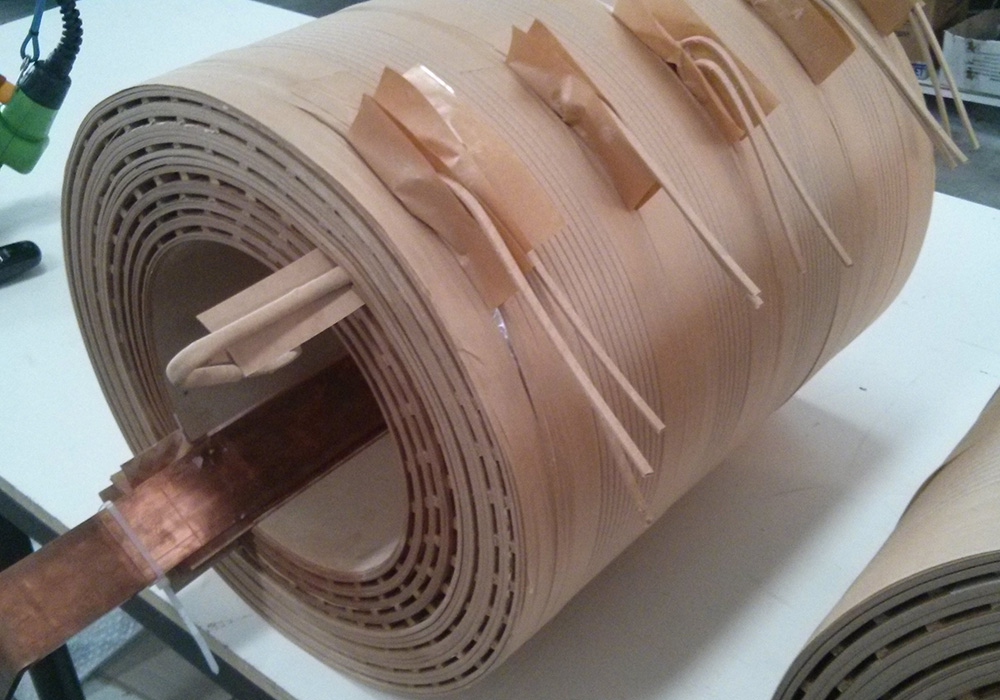

Primary Windings

High voltage windings can be produced separately or together with low voltage windings (primary winding is wound directly on top of secondary winding) according to Client’s construction necessities.

We are also able to build simultaneously two primary windings on the same secondary winding. This is required for double primary tension transformers (es. 10 / 20 kV).

In recent years we have introduced the FLATTENING technology. The procedure reduces the section of the wire, allowing a considerable saving of space and costs, while maintaining unchanged the efficiency of the transformer.

Windings are made with wire or flat wire, in copper and aluminium, and can reach the following measures:

- Copper wires: up to Ø 4 mm, max;

- Aluminium wires: up to Ø 5 mm, max;

- Copper or aluminium flat wire: up to 150 mm2;

- External diameter of the coil: 700 mm, max;

- Height of the coil: 1100 mm, max;

We work with very tight tolerances to maintain optimum performance and maximum efficiency of the winding and we check and test each phase production.

Thanks to our flexible organization, we are able to make individual windings, prototypes or large series.

MACHINERY:

- Horizontal winding machineries with CNC (Computer Numerical Control);

- Flattening machines to reduce the section up to 30%;

- Hydraulic press for cold stabilization of the windings.